Separator Internals

Separator Internals

5.1 Systems For Uniform Liquid Distribution :

After passing through the inlet device the liquid passes through distribution baffles which may be single or matched pair of transverse perforated baffle plates in the liquid zone. Its primary purpose is to provide a barrier and distribute the liquid evenly from the turbulent inlet zone into the calm separation zone.

The distributor also acts to dampen adverse liquid waves and surges which may be caused by incoming slugs. Occasionally, for long separators and/or where the gas velocity is high, additional baffle plates (wave breakers) are installed at the gas/liquid interface along the vessel to prevent wave build-up.

5.2 Single Perforated Baffle Plate (Standard design):

This is a perforated baffle with typically 25-30% open area extending from the base of the vessel to the high liquid level (HLL) or high high liquid level (HHLL). It is used in standard separator applications.

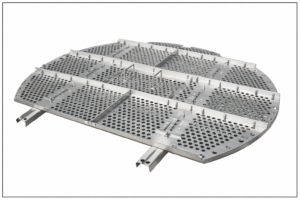

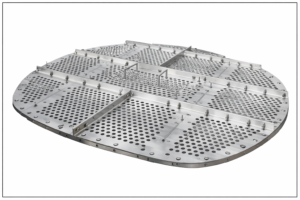

5.3 Dual Perforated Baffle Plate (Enhanced design)

This is a pair of perforated baffles with typically 15-30% open area extending from the base of the vessel to the high liquid level (HLL) or high high liquid level (HHLL). It is used in more difficult separator applications or where the liquid velocity is excessively high.