Mist Eliminator

Mist Eliminator

Mist eliminators find a wide variety of applications such as evaporators, three phase separators, knockout vessels, scrubbers etc. The choice of mist eliminator must be done on the basis of the application requirements. Products are available in a wide array of metals, plastics, thermoplastics to suit a variety of applications.

6.1 Mesh Pad Mist Eliminator:

The mesh pad mist eliminator removes droplets by impingement on surface of a wire. The liquid collected on the filament is drained off under gravity. These mist eliminators provide almost complete removal of droplets down to 3 to 5 microns.

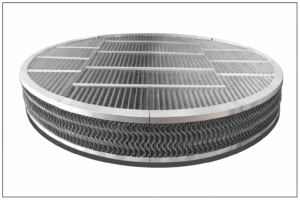

6.2 Plain Vane Pack Mist Eliminator:

The plain vane pack mist eliminator is a high efficiency mist eliminator commonly used for removing entrained liquids from vapour flowing vertically upwards. These mist eliminators use corrugated vanes as a mechanism for mist elimination.

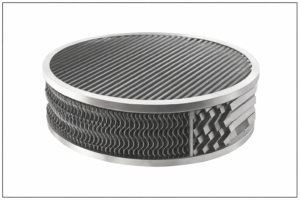

6.3 Pocketed Vane Pack Mist Eliminator:

The high capacity vane pack mist eliminators use a hooked vane mechanism for higher capacity mist elimination. They offer efficient droplet removal and superior resistance to fouling, making them ideal for high-rate horizontal vapour flow.

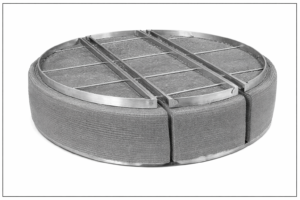

6.4 General Meshpad Configuration:

Wiremesh meshpad mist eliminators consists of a pad of knitted metal or plastic wire mesh usually sandwitched between grids for mechanical support. Units above 600 mm diameter are normally split into sections in the range of 300 to 400 mm to facilitate installation through a normal vessel manway. The pads are cut slightly oversized to ensure a snug fit and eliminate possibility of a vapour bypass either between sections or between pad and vessel wall. Each meshpad is formed from crumpled layers of fabric knitted form a monofilament with the direction of crimp rotated 90 in each adjacent layer to provide a uniform voidage with a high ratio of filament surface.

6.5 Single unit mist eliminator

6.6 Segmented mist eliminator

Material of Construction :

Stainless steel, Nickel based alloys, Titanium, Polypropylene, PTFE, Copper, Kynar. Other special materials available on request.