Liquid Distributor

Liquid Distributor

Proper distribution of liquid at the top of the packing is essential for satisfactory performance of the packed tower. It is important to distribute the liquid flow equally across the column area in order to secure an intensive mass transfer between the phases. H&MT offers a wide range of liquid distributors for different applications.

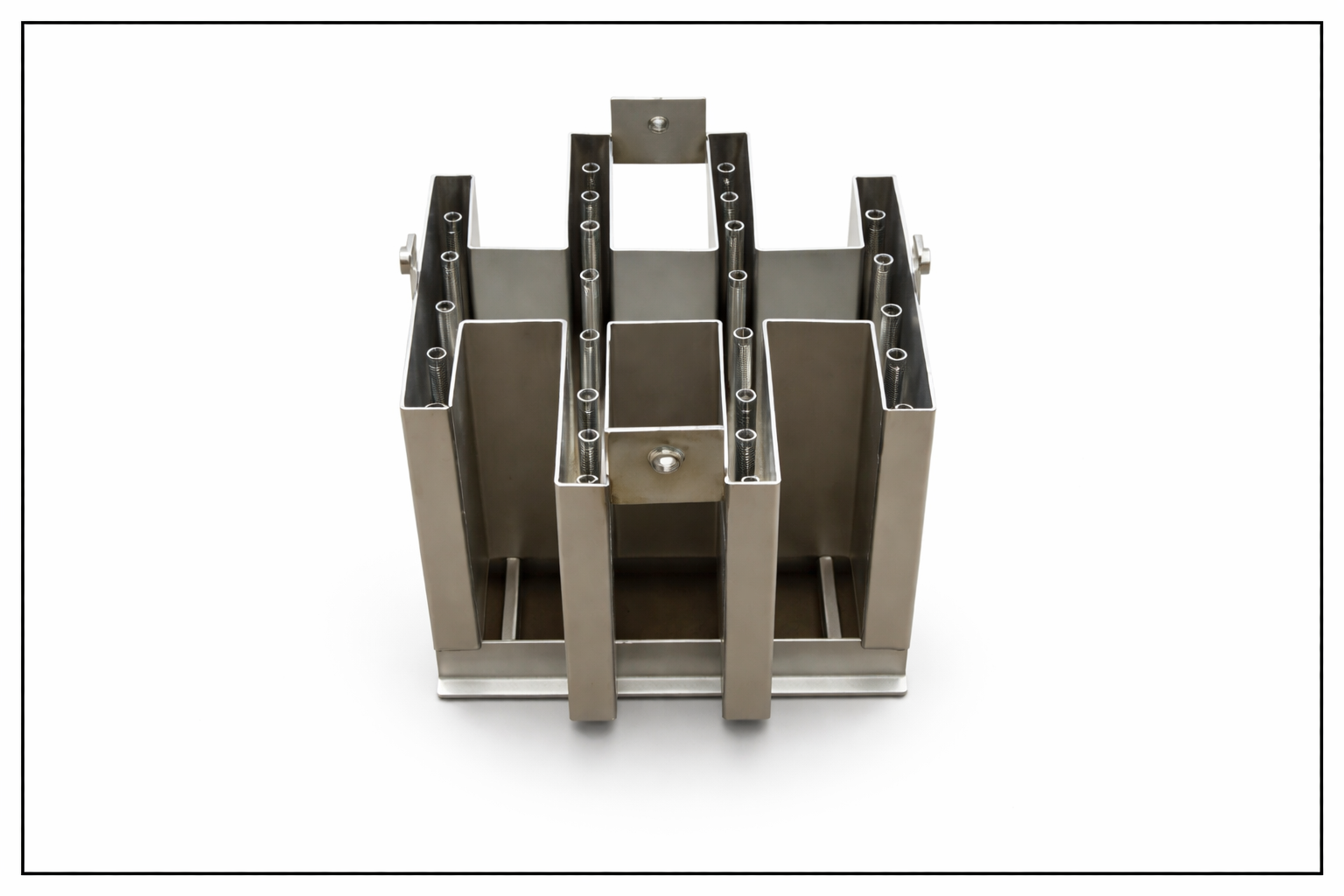

1.1 Channel Type

Liquid is fed into large central channel then distributed through the holes in each channel on the packing. This is used for up to 1500 mm column dia. It can be supplied in single piece or segmented form.

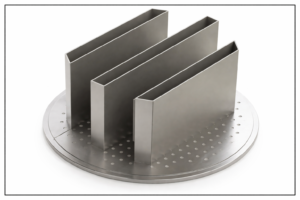

1.2 Trough distributor

It has through type and through-pan type, which is widely used in the heavy liquid and gas load, high viscosity liquid and liquid with suspended solid. This is designed for column dia. 100 mm or above.

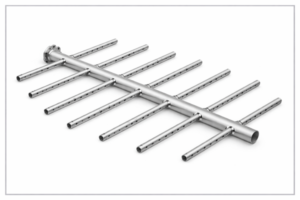

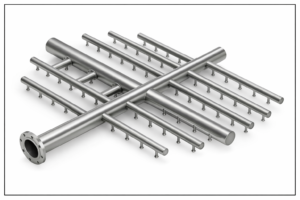

1.3 Pipe-arm distributor

Pipe distributor is be used only for clean service. Single row or double row perforated pipes will evenly distributed the liquid to the packing bed through perforated holes under the pipe. The Pipe-Arm distributor is designed for column ID above 400 mm.

1.4 Spray Distributor

It is used where the complete vetting of packing bed is necessary and generally used in scrubbers, in the wash and circulating reflux. The distributor is designed to create overlapping circles of liquid, which ensures that the entire area below the distributor is covered in liquid. This distributor consists of a main header and laterals with downpipes and spray nozzles.

1.5 Pan Type distributor

Pan type liquid distributors consist of a perforated deck with holes or drip tubes for the liquid and round or rectangular risers for the vapour. This is most conventional type that allow gas to pass the plate through risers while liquid flows through opening in the floor. This is not recommended for fouling applications.