Random Packings

Random Packing

1. HMT-RR ( Raschig Ring Equi.)

HMT-RR is first generation random packing. These are the oldest, cheapest, and previously most widely used packings. The height of the ring is equal to its diameter. The rings are cut from pipes, but in case of metal they are also rolled from metal strips. These are available in various MOCs – Metal, Plastic, Carbon and Ceramic.

Nominal Size | Surface Area m2/m3 | Void Space, % | Packing Factor, F |

25mm | 200 | 91.9 | 137 |

38mm | 127 | 94.9 | 82 |

50mm | 100 | 95.1 | 57 |

2. HMT-PR (Pall Ring Equi.)

These were developed by cutting windows in the Raschig rings and bending the window tongues inward. This opens up the rings, lowers their friction, and improves packing area distribution, wetting, and liquid distribution.

Nominal Size | Surface Area m2/m3 | Void Space, % | Packing Factor, F |

16mm | 345 | 93.4 | 71 |

19mm | 250 | 94 | 63 |

25mm | 209 | 94.2 | 48 |

38mm | 136 | 95.6 | 28 |

50mm | 100 | 95.6 | 20 |

75mm | 70 | 95.6 | 18 |

90mm | 65 | 96.5 | 16 |

3. HMT-HP Rings (Hy-Pak Equi)

Similar to Pall ring, HMT-HP has more internal tongues in an effort to improve the spread of surface area. The resulting claimed efficiency improvement was traded off for greater capacity by making the ring slightly larger than the equivalent Pall ring. Compared to the Pall Ring, HMT-HP has been shown to give better capacity at an equivalent efficiency. HMT-HP is available in metal only.

Nominal Size | Surface Area m2/m3 | Void Space, % | Packing Factor, F |

30mm | 179 | 96 | 43 |

45mm | 125 | 96.4 | 26 |

60mm | 98 | 97 | 18 |

90mm | 85 | 97.5 | 15 |

4. HMT-CR (CMR Equi.)

HMT-CR is third generation packings. These rings are similar to the Pall ring, but have an aspect ratio (height to diameter ratio) of 1:3, compared to 1:1 in the Pall ring. The lower aspect ratio orients the particles with their open side facing the vapor flow, thus reducing friction, and exposing more surfaces to mass transfer. HMT-CR is available in metal, plastic and ceramics.

Size | Surface Area m2/m3 | Void Space, % | Packing Factor, F |

1 | 251 | 96.4 | 40 |

1.5 | 202 | 96.4 | 29 |

2 | 145 | 97 | 22 |

2.5 | 123 | 97 | 17 |

3 | 103 | 97 | 14 |

4 | 76 | 98.5 | 10 |

5 | 43 | 98.9 | 8 |

5. HMT-IR (IMTP equi.)

HMT-IR is third generation packings. It combines the high void fraction and the well distributed surface area of the Pall Ring with the low aerodynamic drag of the saddle shape. Compared to the Pall Ring, it provides a more open shape and improved liquid spread, while incorporating adequate mechanical strength and entanglement resistance. HMT-IR is available in metals only.

Size | Surface Area m2/m3 | Void Space, % | Packing Factor, F |

HMT-IR 15 | 290 | 94.7 | 51 |

HMT-IR 25 | 230 | 96.7 | 41 |

HMT-IR 40 | 150 | 97.3 | 24 |

HMT-IR 50 | 98 | 97.3 | 18 |

HMT-IR 90 | 59 | 98.1 | 12 |

6. HMT-IS (Intallox Saddles Equi.)

The HMT-IS packing is like a berl saddle packing. These packings are mostly used in gas absorption application.

Nominal Size Surface Area m2/m3 Void Space, % Packing Factor, F 25mm 206 91 33 38mm 140 91 25 50mm 150 97.3 24

7. HMT-SIS (Super Intallox Saddles Equi.)

The HMT-SIS is an improved version of HMT-IS packing that provides better liquid distribution, low liquid hold up, high capacity and improved efficiency for mass transfer.

Nominal Size Surface Area m2/m3 Void Space, % Packing Factor, F 25mm 210 90 33 38mm 110 93 21 50mm 89 94 16

8. HMT-Telpak ( Tellerette Equi.)

HMT-Telpak are a high efficiency plastic tower packing designed for use in wet scrubbers, cooling towers, mist eliminators, absoption columns and gas strippers. They provide a surface area equal to many other packings but with much greater liquid surface availability.

Nominal Size Surface Area m2/m3 Void Space, % S 180 89 M 127 89 L 102 90

9. HMT-SF (Snowflake Equi.)

The low aspect ratio (height to diameter), even lower than that of CMR, orients the HMT-SF particles with their open side facing the vapor flow. This reduces friction and permits good liquid drainage from the ribs of the packing.

Nominal Size Surface Area m2/m3 Void Space, % 90mm 100 95

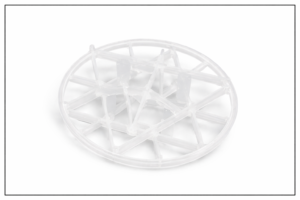

10. HMT-HF Rings

The HMT-HF Rings are high performance tower packings. The strong lattice type provides high mechanical stability together with a very high void fraction. High capacity of gas and liquid flow rates, extremely low pressure drop, very low wall flow and low sensitivity to pollution and fouling characterize the HF Rings. If HF Rings replace conventional tower packing, then the flow rates in existent columns can be considerably increased or the energy consumption can be significantly reduced.

Materials: PP, PPH, HDPE, PVC, C-PVC, PVDF, PFA, others on request.

Nominal Size | Surface Area m2/m3 | Void Space, % |

15mm | 313 | 91 |

25mm | 214 | 91 |

38mm | 150 | 94 |

50mm | 110 | 94 |